Car engine is basically an internal combustion engine where power is generated through expansion of high temperature and high pressure gases A lot of heat is generated due to the combustion gas and the friction of mechanical parts for sustained operation these excess heat should be removed from the engine and kept at operating temperature.https://amzn.to/4baVwia

Cooling system parts:

Parts involved in cooling the engine are :

1 water pump

2 radiator

3 thermostat

4 coolant temperature sensor (CTS)

5 Coolant ( Antifreeze+ water)

Water pump

Water pump is the heat of the cooling system which pumps the coolant it consists of an impeller a pulley flange and an O – ring the impeller is driven by the engine drive belt through a pulley

Radiator

The radiator is a heat exchanger used to transfer the excess heat developed by engine to the atmosphere the radiator having an inlet port outlet port, a drain plug and a radiator pressure cap the radiator pressure cap plays a vital role in the cooling system

Thermostat

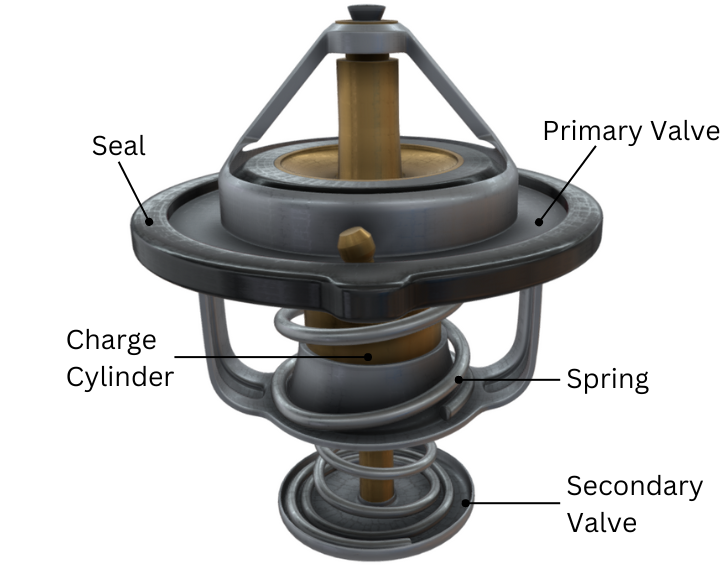

The thermostat is a valve which regulates the flow of a coolant and helps to maintain the proper operating temperature for the engine the thermostat consist of a frame, charge cylinder main valve ,main spring bypass valve and secondary spring

Coolant temperature sensor (CTS)

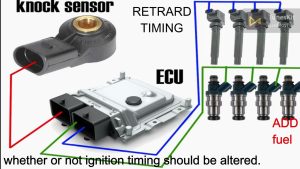

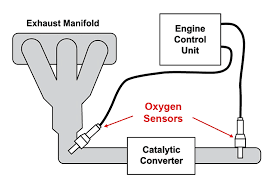

It is used to monitor the engine temperature the ECU will use this data to manage fuel injection and ignition time some engines have more than one coolant temperature sensor the data is also used to control the radiator fan and to update the temperature gauge on the driver console it consists of a sensing probe and an electrical connector most coolant temperature sensors are the negative temperature coefficient type which means the temp increases the resistance will decreases the CTS is a can be two pin type or a three pin type depending on the make of vehicles

Working

How these part working together ?

Pistons are contained inside the engine block in which each of them will function above the engine block comes the head gasket which provides sealing between engine block and engine head It avoids compression leaks and oil or coolant leaks into the cylinder above that comes the engine head the engine having a safe passage through which the coolant can flow without entering into the cylinder or mixing up the with the oil this pessage is known as water jacket

Let’s put the part one by one and how it’s works

The water pumps the coolant throughout the system with the help of radial impeller it’s driven by engine itself using a serpentine belt the serpentine belt also drives the power steering pump, alternator ,AC compressor but for now only water pump shown now the connections the thermostat bypass hose ,the thermostat housing inside the thermostat the radiator and the radiator fan the lower radiator hose the water pump outlet hose the upper radiator hose the coolant expansion tang expansion bleed hose coolant overflow hose so finally let’s get into the working starting with the thermostat the thermostat is actually a valve which regulates the flow of the coolant it will always be covered in the coolant so that the temperature can be sensed let’s start the operation from a cold engine when the engine is cold the bypass valve stays open so the coolant bypasses the radiator and recirculates through the engine this helps the engine to heat up to the operating temperature quickly eventually the coolant temperature increases by absorbing the heat from the engine .once the coolant starts to reach higher temperature which is usually between 160 to 190fahrenheit the bypass valve will start to close and main valve will start to open this allows the cold coolant from radiator flow to the engine side and the hot coolant from engine side to the radiator in most cars the coolant temperature sensor is located near the thermostat housing it will turn on the radiator fan of the coolant to the radiator side at high temperature now the hot coolant in the radiator will release its heat to the atmosphere with the help of the fan at the same time the cold coolant received from the radiator will start to absorb the heat from the engine for the next cycle heating liquid inside a closed system always builds up the pressure

How to maintains the pressure ?

The role of radiator pressure cap it consists of a spring loaded valve mechanism which will respond to higher pressure reaching a pressure about 15psi will push the pressure cap valve and the coolant flows the expansion tank until the pressure goes down to operation level and when systems cools down the vacuum inside the system sucks back the coolant from expansion tank in case if there is to much pressure build up in the system due to trapped air or other failures the coolant in the expansion tank will be pushed out through the overflow hose

Heater system

The car heater system is a part of the engine cooling system the heater system consists of the heater core, inlet and outlet hose a heater control valve which is optional and cannot be found in all vehicles the heater core act as a radiator dissipating heat from the hot coolant to the vehicle interior using a blower pump,alternator,AC .

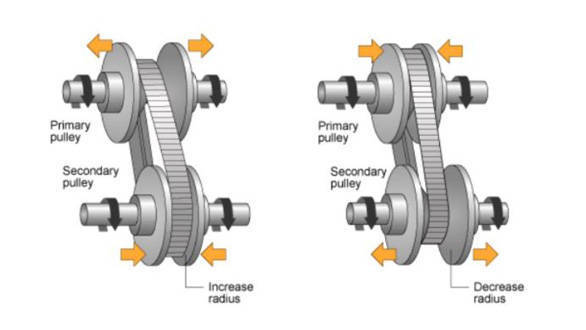

input speed

input speed