Arts & Food

Fashion

<introduction>

BMWs are renowned for their powerful engines, cutting edge electronics and excellent handling. These car have their problems even though they are excellent in many aspects the error message “” drivetrain malfunction that appears on the dashboard display is one problem that some BMW owners have been reported

The purpose of this error message is to alert the driver to a potentially serious problem, which can be concerning it doesnot however always indicate that the car is about yo breakdown everything you need to know about the BMW drivetrain malfunction message including how much it will cost to fix

Meaning

BMW employs self monitoring technology to record malfunction and notify the driver of an impending or existing problem A drivetrain consists of the following components : axles, driveshafts, transmission, differentials and if included a transfer case the drivetrain malfunction message doesn’t always mean that the drivetrain is the only source of problem

Another way to set the message is for powertrain related issues

Causes

There are several potential causes because both powertrain and drivetrain related issues can result in the drivetrain malfunction message this error message is typically caused by an engine or related problem the most frequent reasons are as follows

Defective or won spark plugs

Dirty or faulty fuel injectors

Fail ignition coils

Faulty high pressure fuel pump

Poor fuel quality

Clogged catalytic converters

How to fix?

We want yo stop the drivetrain malfunction warning from staying error the error message may be accompanied by additional warning messages or fault codes such as maximum drivetrain output not available which is frequently the case the diagnosis of the warnings underlying cause is aided by these additional warnings some action we can take to fix the drivetrain malfunction issue:

Check the fluid levels

Low engine frequently results in the drivetrain malfunction message if the fluid level is low check the engine for leaks if necessary top off the systems with the appropriate fluid

Check vacuum hoses for air leaks

The positive crankcase ventilation valve is prone to frequent failures

Use higher grade fuel

The drivetrain malfunction message has been attributed to low quality fuel according to some BMW specialist and customers buying fuel with a higher octane from a well known gas station lowers the chance of receiving tainted or subpar fuel

A common cause of drivetrain malfunction error is worn spark plugs the error message will usually be accompanied by misfire codes that are stored raw fuel entering the exhaust from a misfired cylinder is a common cause of clogged catalytic converters

How to reset?

Restart the engine after tuning the car off for five to ten minutes to reset it if the issue recurs, flaws are found and repairs are probably required

Cost to fix

The cost of fixing a BMW drivetrain malfunction can vary significantly based on underlying cause. A drivetrain malfunction error repair won’t break the bank most of the time there have been some reports of expensive repairs up to $2500

If there has been significant damage to the engine repair cost increase even more its also important to take a model specific costs into account

E. G The same part will cost more on a 7 series than a 2 series

We advised looking up relevant technical service bulletined service campaigns recalled and warranty coverage before making any repairs

< Repair cost estimates >

Tune up $200-$300

Ignition coil replacement #65-$600

PCV replacement $50-$150

Fuel system clean $120-200$

Cat converters replacement $1500-$3000

< Conclusion ::: >

The BMWs model like 3series and 5series are frequently modified drivetrain and powertrain problems can result from specific vehicle modifications one BMW service bulletin states that drivetrain malfunction may be caused by aftermarket components or tuners

The drivetrain malfunction error is typically accompanied by additional message

Diagnostics trouble code consequently the cause of fault shouldn’t be to mysterious

Repairs can involve anything from a straightforward gas tank or fuel additive replacement to engine, transmission, powertrain control module reprogramming the purpose of warning message is to prevent damage to vehicles when the drivetrain malfunction is active we advice against driving for extended period of time get your car scanned and start with a straightforward engine restart inspect the fluid levels in car looks for any leaks and stay away from aftermarket performance components as they may also contribute to the issue

Intro

![]()

Purchasing a vehicle depending on their use case today we will compare two popular types of suspension and we will try to make a conclusion which fits best

Double wishbone suspension pros :

Upper wish bone

Suspense and its pros improved handling double wishbone suspension improves handling and stability especially during cornering its design allows for dynamic camera changes in the middle of the corner maximizing the contact with the road this result in improved traction and control especially on uneven or difficult terrain many double wishbone designs allows the rear outside wheel to tow in when the suspension is compressed this allows the car to enter the corner more quickly as a result the vehicle feels more agile and responsive

Adjustable geometry :

It typically provides far more alignment adjustability with more camber caster and tow setting available this adjustability enables the suspension geometry to be fine tuned to meet specific driving preferences or performance requirements better it is beneficial for car enthusiasts who autocross or race their vehicles now about cons complexity and cost when compared to makers struts double wishbone suspension are more complex and intricates in design they necessitate the addition of additional components such as upper control arms upper ball joints and additional bushings which can lengthens development time and increase manufacturing costs the systems complexity can also make repairs and replacements more time consuming and costly increased weight the additional component of double wishbone suspension can add weight resulting in higher unsprang mass this this extra weight may have a minor impact on fuel economy and overall vehicle performance however advance in lightweight material and engineering techniques have helped to mitigate this disadvantage in modern designs now lets head to the McPherson strut suspension and lets talk about its pros easy and inexpensive when compared to double wishbone system makers strut

Suspension are simpler in design with fewer components their small size makes them easier to install and maintain resulting in lower manufacturing costs this ease of use also translates into faster and less expensive repairs

Space efficient :

replacements space efficient macers struts are space efficient taking up less space in the engine compartment this enables nore efficient packaging freeing up space for other components or paseenger accommodations it is freeing up space for other components it useful in vehicles with limited engine based space good balanced mcferson struts offers a good balance of ride comfort and handling their design provides sufficient shock absorption and stability resulting in a smooth and controlled ride macers strut suspension systems strike a good balance for daily driving the economy cars and even some light duty trucks even though they might not match thr handling performance of double wishbone suspension but this suspension has its own cons limited flexibility there are fewer adjustable options for macers struts then for double whishbone suspension the lack of adjustability might nake it more difficult to fijd tune the suspension characteristics to meet certain performance standard or driving preference this might be limiting for enthusiasts looking for a highly customised suspension setup however anthusiasts who own cars with mcferson

Stretch suspension often have access to aftermarket option

E. G

Additional chambers adjustment are provided by camber plates and aftermarket control arm its also possible that spoke aftermarket suspension part provides more caster setting increased body roll when suspension part provide kore caster settings increased body roll when cornering nacres struts tends to cause more body roll than double wishbone suspension because the wheel are interconnected modification to one could have an impact on the other potentially decreasing overall handling responsiveness and precision antiroll bars and appropriate suspension tuning however lessen this disadvantage conclusion :

every suspension system including macers strut and double whisbone has advantages and disadvantages macron suspension are better in term of cosr and space but double wishbone suspension are better in term of handling and adjustability which suspension configuration is ideal for you will ultimately depend on your specific use case remember your personal preference your budget and the intended uses of your car in order to choose the suspension system that best fits their particular vehicles models manufacturer carefully consider these factors balancing performance cost abs overall customer satisfaction.

Intro

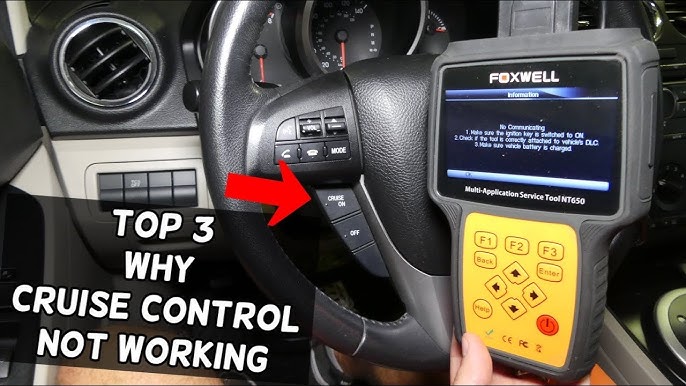

A short while ago cruise control feature was limited to certain car models these days cruise control seem to be standard on almost every type of car on the road while it my insignificant not being abl3 to use the continent cruise control features can make any road trip less enjoyable CC malfunctions must be diagnosed in order to fixed and used again

Now examine the typical reason why CC doesn’t work

1 check engine warning light :

When check engine warning light illuminates it typically indicates an issue with either your engine or transmission

Cruise control system may be turned off as a safety measures by the engine control unit if it find this issue CC system will remain deactivated until the engine problem is resolved

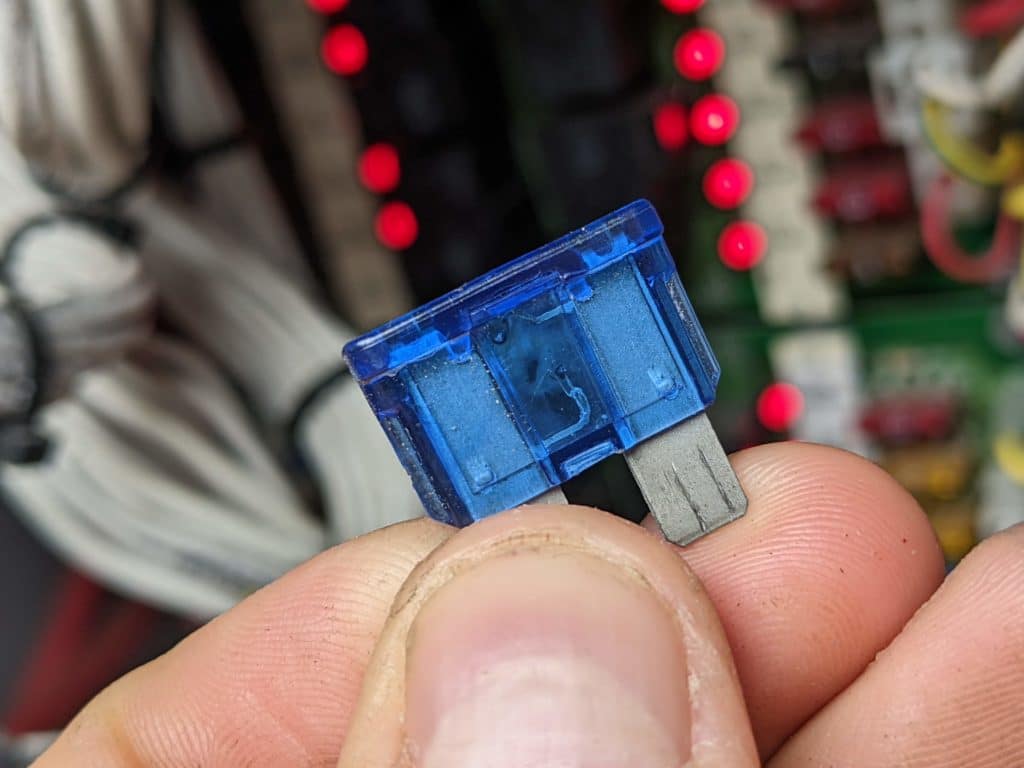

2 Blown fuse :

Fuse protection applied to CC system electrical components it is possible to blow a fuse just like inside your home as a result fuse is changed CC system will be disabled

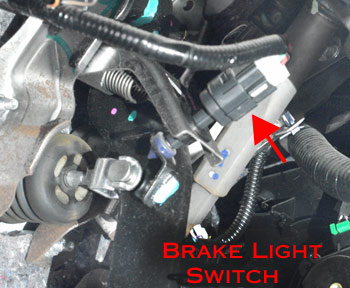

3 Brake light switch :

To disable CC press the brake pedal the CC system has to detect the brake light switch this function will turn automatically until the brake light switch problem is resolved if it is unable to detect the switch. Brake light staying on could be result of broken broken light switch

4 switch malfunction :

Cruise speed is adjusted using the CC switch to maintain the acceleration speed this data is sent to CC module and engine control unit the acceleration if the contact inside the CC switch were to wear out the system will completely deactivate and remove the current cruise acceleration setting in response

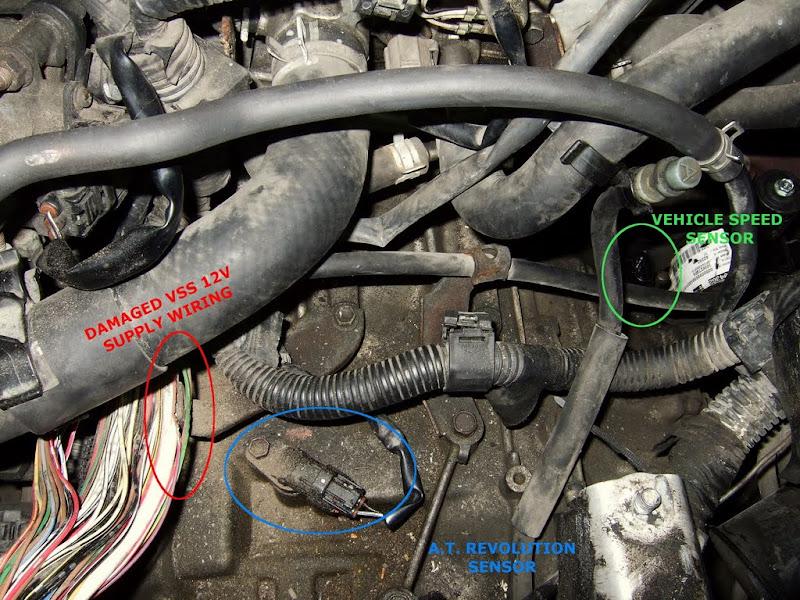

5 vehicle speed sensor :

The engine control unit and the CC modules receive speed information about the vehicle from the few vehicle speed sensors found in the majority of cars The CC module will only receive this data from the vehicles speed sensor if that is how quickly the vehicle is travelling the CC system will automatically deactivate if the speed sensor malfunction and the module is unable to detect the speed

5 electrical issue :

The CC system is connected to multiple electrical components when this feature stops working definitely check the connectors wiring harnesses and ground straps verify that the voltage source is still providing the system with power. The Control not working would make sense if any of these part were broken or loose

6 throttles bottle issues :

Two throttles cables are used in older cars with cruise control one for gas pedal and another for CC system

These cables might elongate with time the CC system will not be able to operate the throttle plate correctly if the cable is broken or has stretched

7 repair costs :

The cost of repair varies based on the nature of the problem as well as the make and model of car then you get a idea of what to budget for from this section

Examine most frequent causes of CC issues and the approximate cost of replacing or repairing them

Blow fuse 5 to 30 $

Quick and affordable to replace

Faculty cruise control 100 _200$

Faculty brake light switch 50-150$

Defective speed sensor 100-300$

ABS- Related problems 200-1000$

The internal combustion engine contain numerous fictional part the friction causes them to overheat to reduce friction and remove heat car used a lubrication system this system delivered lubricants to all friction part the most viral part are fact with lubricant under pressure the other part are relay on gravity and splash feedsWorking :

:

We examine whole engine lubricating cycle fill up engine with motor oil is drained into oil sump along the available roots in this case it happens timing drive cavity and the deliciated channels the oil is stored in oil sump that has oil dipstick attached to it oil pick up in oil strainer when we starting engine it activated the oil pump which drowse oil and creating pressure at the outlet in this example the pump is operated by change drive from the crank shaft the pressure relief valve control the lubricating pressure and open when the safe miserable pressure is exceeded it is mounted on either on oil pump

Let’s look how oil pump work

You can see several gear pump act as oil pump they can featured by either internal and external gear mashing in external gear pump there is a crescent partition, gerotor pump and oil crescent partition another variety is variable dischargable oil pump

The pressure oil goes into oil pump in the cylinder oil blocks in the gallery having been cleaned a wine metal dust and oil impurities by passing into an oil filter if the filter become to clock the oil will pass through the bypass valve without being clampsed so replace the filter everytime you change your oil

The filter outlet are featured with oil pressuring sensor

The oil run along the cylinder block oil gallery to the crank shaft main journals which lubricates the main journals under pressure this produces an oil coating that minimises friction the oil flows in the crank shaft channels which lubricates the rod journals in its connecting rod bearings let’s make a closer look at oil crank shaft pessage the presurized oil is pushed out in the connecting rod bearings the rotation of crank shaft spread all over crank case lubricating the cylinder wall piston piston things and partially the timing drive this also generate an oil mist in the crank case the splash oil thus run out in the oil sump simultaneously some oil flows through the oil gallery in cylinder block the cylinder have eventually reaching the camshaft journals they pushed out the lubricating timing drive by gravity and splash feeds the oil then returned into oil sump and cycle start all over again

The system should contain at least one oil pressure sensor which control system functioning pressure sensor can be placed in the different part of the system including downstream of the filter and the forehead of oil gallery and sometimes this is featured with several sensors e.g upstream and downstream of the filter when the oil pressure in the lubricating system is low the warning light in filter iliminates on the dashboard more complex system may include oil temperature sensor, oil level sensors and air water cooled radiators cooling a radiator is also featured with various coupling scheme there is also approach to lubrication and cooling of piston, and piston tanks such as extra oil pessage in connecting rods oil holes at bottom of connecting rods and oil jet nozzles in the cylinders block

Lubrication is also required for optional system such as turbocharger some control function can be performed by the lubrication systems thus pressurise the motor oil is essential for the hydraulic lash adjusters some variable valve timing drive hydraulic tensioner

To prevent any access oil in the combustion chamber piston are out fitted with oil control rims that removes most of the oil in the cylinder walls this valves is valve stem seals and prevent excess oil from entering through valve stem seals various gasgets oil seal between the engine stationary moving parts heating preventing oil from exceeding the engine (rear covers and rear crank shaft oil seals)

finally keep in mind oil changes are crucial since oil become contaminated overtime causing it to degrade so change your oil regularly from long dues of dirt oil result in severe engine vared.

The Components found in a typical drum brakes system are we have the back plate assembly ,the brake drum ,wheel, nuts

First we will take a look at detail of back plate assembly and brake drum

Brake drums

Brake drums are made up of highly cost oil which conduct heat well and this slot away the drum rotates on its axle and wheel providing the friction surface when the brakes are applied

Back plate assembly

It contains over components requires to operate the drums brakes let’s explore each components in term the back plate remain stationary and provides a fixed space for other components to attached

Next we have brake shoes

It consists of steel frame fitted with a friction material or brake lining this material is bounded on the outer phase of shoes frame there is a wheel cylinder

A wheel cylinder is connected to hydraulic system and contained piston which are force outward by hydraulic pressure when the brakes pedal is pressed the shoe retaining spring pull the brake shoe down on to the back plate keeping in its position A tensioning spring is fitted to the shoe when brakes pedal is released the hydraulic pressure is reduced allowing the tensioning spring to withdrawals the wheel cylinder piston and pulled the brake shoes are away from the drum this allows to wheel to rotate once more freely

Drum brakes are just used as self adjusting mechanism the adjustor just take as excessive clearance creating as a friction material on the brake shoes Vas reducing the current movement of shoes this bring the brake shoes closely to the drum and maintains the consistent pedal field and braking response finally we have hand brake mechanism the hand brake cable enters the drum into the back plate and connect the brake shoe liver arm cable electronic and hydraulic system are founded handbrake but in our example cables are used to activate the rare brakes when the hand brakes pulls upward the cable is tensioned forcing the brake shoes outs against the brake drum the hand brakes maintained the tension and till the hand brake released .

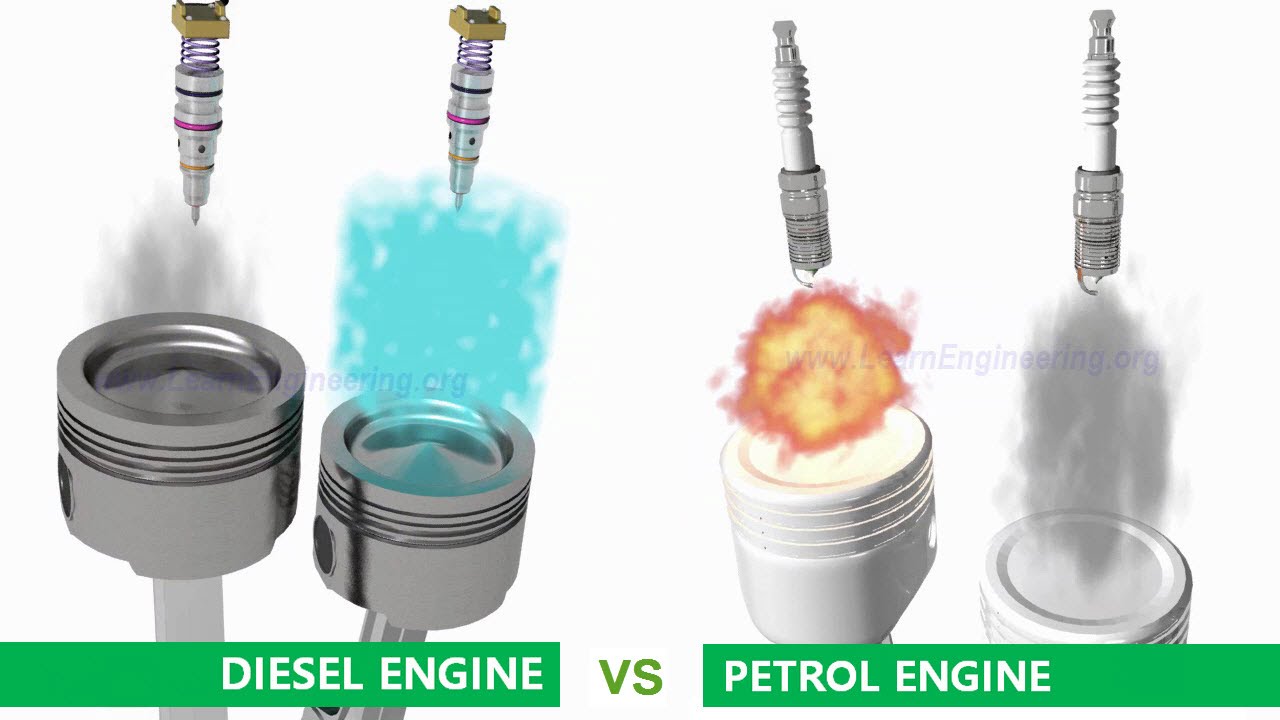

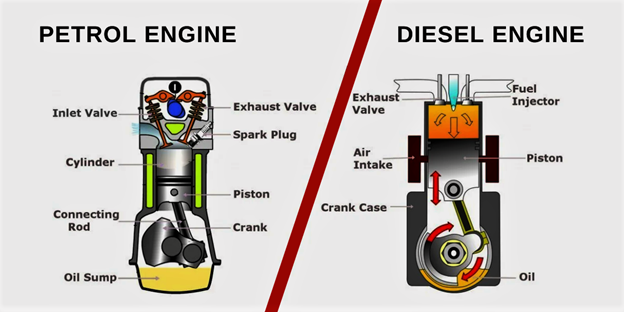

gasoline engine and diesel engine are the two most common internal combustion engine even though the operation seem similar but there have some interesting differences each having advantages over other

first engine have basic force stroke

intake

compression

power

exhaust

there are difference between the two engines two to the difference way the fuels burns

gasoline readily easily evaporates so it’s gets mixed with air officially ( low flash point -43°C) highly volatile as a result just a spark is often to produce smooth combustion in a well premixed gasoline engine on the other hand these are not properly mixed with air highly flash point 52°C less volatile (diesel) however if diesel is sprayed into high temperature air spontaneous combustion is occur this shows that the gasoline engine have should fuel air mixed

while in diesel engine mixing happens during only combustion

this is why diesel engine using fuel injector

while gasoline engine using a spark plug

you might have noticed that gasoline engine are might less noisy and less vibrate compared to diesel engine this is because combustion process in a premixed mixture is smooth and propagate wells

but in a diesel engine the combustion could begin anywhere in the combustion chamber

and turn out to be a uncontrollable process for this reason due to reduce the excessive vibration and noise problems diesel engines requires a more rug instructional design than gasoline engine this is why gasoline engine is more preferable for life weight application

diesel engine is only compressing only the air can be achieved a good compression ratio

C.R = V clearance /V total (C.R = 18-24) but in a premixed gasoline engine such a high compression ratio(C.R = 8-10) is not possible the higher the compression ratio better is the efficiency of cycle

interesting question many people wonder is

Diesel in gasoline engine ?

diesel in gasoline engine will not even cost fire the reason is simple less volatile and not well mixed properly with air and sparking will not initiate combustion

on the other end put

gasoline in diesel engine ?

you are spraying highly volatile fuel in a chamber of highly compressed hot air this will lead designation rather than smooth combustion eventually the engine components will be damage that’s a big no for gasoline in diesel engine.